Leadership and Business development

Posted on 1st April 2022 at 12:32

This is the most important image I have ever come across for the creation and development of a business, its Leaders, and its people.

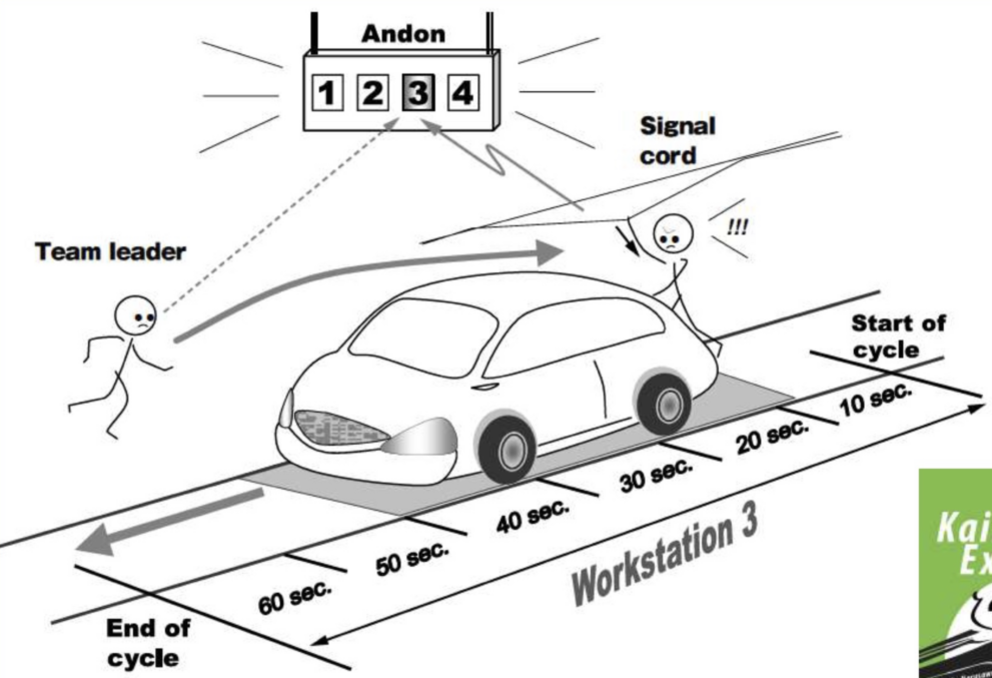

This diagram is from the Toyota Way handbook, so I am told. I came across it in the Kaizen Express manual. It has been such an important diagram for my Lean thinking development and my passion that is has remained my screensaver for over 10 years. Even today, as I develop my skills and capability as a Lean Leader, I see more depth and structure within this diagram, let me explain.

Initially, it showed me the importance of a team leader coming to the aid of a team member who was having difficulty on the production line. The operator working within a cycle time of 60 seconds has a problem, so they pull the signal cord which lights up the Andon and the team leader knows where on the assembly line they need to run to help their team member.

This showed me that the role of a leader is to support their people in bringing delight to their customers.

But let's look deeper.

The car is on a track that is divided into 10-second increments. This allows the operator to know whether they are ahead or behind the time sequence to achieve the 60 seconds objective.

The only way they would know that this exists is because the process that they are following has been designed by the leader to achieve each one of the 10-second increments and thereby deliver the car by the 60 second end of cycle. In other words, the process has been designed and validated by the leader to ensure that the operator can achieve the desired quality output within the time defined.

How many of the processes that you have in your business has been designed and tested to this level of capability?

The only way the leader knows is because the leader has been part of the design.

Next, the operator is trained to deliver the capability of the process within the 60 seconds. We know this because the team leader is no longer standing beside the team member but has validated their training and capability so they can be left alone to deliver the required output within the time defined at the required quality. Also, part of the key instructions of the process is that if you cannot achieve the requirement within the defined timing segments (notice the 10 seconds segments) then the team member must not try and fix/fudge the problem but immediately stop and call for help.

Blimey, you mean they stop the production line!

Yes!

The only way that real problems are dealt with is if you stop the line. If you push the product to the side or try and make a temporary fix, you will never understand the real problem that has caused the issue to occur. Giving the power to the team member to stop the line allows for a real understanding of the problem so that it can be found then and there.

Next we can see in the diagram that by pulling the Signal cord, the Andon light is triggered. This is the visual management in the workplace to show the leadership team where problems are taking place and where problem-solving needs to be implemented immediately. As you can see, the team leader, or the manager of the process is running to help fix and identify the root cause of the problem.

So why is this important?

The leader is the person that designed the process (or is the most knowledgeable) that the operator is working on. They understand the detail of the process, and they have also made improvements for the process that has developed it even further. They are people that have the responsibility for ensuring the quality and delivery requirements are met for the customer. They now need to run to the problem, identify what can be fixed right now, and understand the details of why the problem occurred. By understanding this detail they can then carry out corrective actions both short-term and long-term. It is the long-term corrective actions that will stop the problem from coming back ever again.

And this is the true power of this image.

By:

Designing the process

Giving the power to the team member to stop

By seeing where the problems are

By getting involved instantly to stop and fix

And then problem solving

The team leader demonstrates the real power of continuous improvement within any process.

So, this means to us that in our businesses no matter what size, we need to:

Design the process for success,

Give the power to our people to stop when they are unsure or do not know what to do or the quality is wrong,

Put in place the processes that allow us to see where these problems are.

Know that we have to go and help and solve these problems that are taking place.

In this way we will develop the most successful problem-solving process in the world.

Do you agree? To what level have you designed your processes? To what level have you developed your people to know if the process is running right or running wrong? How committed are you to fixing the real problem right here, right now?

If you would like to discuss more, please reach out to me.

Granger Forson.

Tagged as: Business development, Leadership

Share this post: